Nanomaterials

At MSU, a growing number of Spartan innovators are harnessing the unique properties of nanomaterials into their research. These engineered nanomaterials, 1-100 nanometers in size, have cutting-edge applications in advanced pharmaceutical delivery, engineered materials, environmental remediation and a multitude of other ventures.

Their very small size makes them simultaneously promising and challenging. Nano-sized particles can enter the human body through inhalation, ingestion and through the skin. However, few occupational exposure limits exist specifically for nanomaterials—and those that do may not provide adequate protection for long term health effects.

If you are currently using nanomaterials, or considering their use, please contact Tyler McCord for an in-person consultation to determine appropriate safety controls. Successful safety assessments will result in the following outcomes, where possible:

- Handled and stored in solution: Acquire nanoparticles in dispersion or in bulk solids, and handle in powder form only when no other options exist.

- Minimum quantities handled and stored: Limit the amount of nanomaterials stored and handled in the laboratory to minimize potential exposure and hazards.

- SDSs have been reviewed: Safety Data Sheets (SDSs) for all nanomaterials must be available and accessible to all laboratory personnel. All employees should review the SDSs for the nanomaterials they will be handling.

- Equipment marked where appropriate: Clearly label all equipment, containers, and designated areas where nanomaterials are stored or handled to ensure awareness of potential hazards.

- Handling restricted to trained personnel: Only individuals who have received the appropriate training, as outlined in the "Training" section of this policy, are permitted to handle nanomaterials.

- Proper written policies and documents: Written documentation such as SOP documents and procedure instructions are developed, as appropriate to the particulars of your experiments.

Nanomaterial Safety Document (PDF)

Nanomaterial Safety SOP Form (DOCX)

-

Engineering Controls

Activities that are likely to release nanomaterials should not be performed on the open bench. This can include weighing dry materials, preparing suspensions, or cutting, sawing, drilling, and sanding bulk solids containing nanomaterials. These activities should be performed in a fume hood (or other vented enclosure), biological safety cabinet, glove box or a vented filtered enclosure.

Controls beyond those described above are warranted when aerosol generation of nanomaterials will be extensive, or will involve acutely hazardous parent materials. These controls might include a higher level of containment and/or HEPA-filtration or other cleaning of exhaust. For assistance with risk assessment, contact EHS at 517-355-0153.

-

Personal Protective Equipment

- Always wear long pants and closed toe shoes when working in the lab.

- Always wear disposable nitrile gloves and lab coat when handling nanomaterials, with the gloves covering the cuff of the lab coat.

- Wear face shield and goggles where splashes may occur.

- Only launder lab coats using University laundry services. Do not take lab coats to private homes.

- When ventilation controls are deemed inadequate, respirators may be needed. Respirator use should comply with MSU’s Respiratory Protection Program.

-

Work Practice Controls

- When possible, acquire nanoparticles in dispersion or in bulk solids, and handle in powder form only when no other options exist.

- Do not store or consume food or drink in areas where nanomaterials are handled.

- Do not apply cosmetics in areas where nanomaterials are handled.

- Wash hands before leaving the work area and after removing protective gloves.

- Avoid touching the face or other exposed skin when working with nanomaterials.

- Change gloves regularly (at least every two hours) and wash hands at the time of the glove change.

-

Laboratory Design

- Set up a designated area for work with nanomaterials and suspensions away from entrances and high traffic areas. A designated area may be an entire laboratory, a section of a laboratory, or a containment device such as a laboratory hood or glove box.

- Post signs indicating hazards, personal protective equipment requirements, and administrative control requirements at entry points into designated areas where nanomaterials are handled.

- Handle dry nanomaterials in a fume hood, biological safety cabinet, glove box or a vented filtered enclosure. Do not work on the open bench with dry nanomaterials.

- Aerosol producing activities (such as sonication, vortexing and centrifuging) should not be conducted on the open bench. Perform these activities in a fume hood, biological safety cabinet, glove box, or a vented filtered enclosure.

- Nanomaterials should be stored in labeled containers that indicate their chemical content and form.

- Liquids or dry particles should always be stored in unbreakable, tightly sealed containers.

- Secondary containment should be used when appropriate.

- Clean areas where nanomaterials are prepared and/or administered immediately following each task and each day after work with the nanomaterials is complete.

- Daily vacuuming of benches and floors with a HEPA vacuum should be performed in labs that handle dry nanomaterials. Only use HEPA-rated vacuums; using non-HEPA vacuums can release nanomaterials directly into the surrounding atmosphere. HEPA vacuuming is not recommended for reactive materials, as they may react with other materials collected in the vacuum, or with components of the vacuum itself.

- Use wet wiping or HEPA vacuuming to clean large surfaces (i.e. floors, benches).

- Using wet methods, routinely clean containment device interiors, equipment, and laboratory surfaces where there is potential for nanomaterial contamination. Consider the potential for complications due to the physical and chemical properties of the material to avoid reactions with cleaning agents.

-

Transport & Shipping

- Transport dry nanomaterials in closed containers.

- Handle solutions containing nanomaterials over disposable bench covers.

- Transfer nanomaterial samples between workstations (such as exhaust hoods, glove boxes, furnaces) in closed, labeled containers.

- If weighing dry powders and the balance cannot be located in a fume hood or BSC, tare a container then add the material to the container in a hood, then seal the container before returning to the balance to weigh the powder.

- Complete dangerous goods declaration or shipping papers for offsite shipments of nanomaterials in accordance with the IATA and DOT regulations. Contact EHS for instruction on shipping potentially hazardous materials.

- Materials sent offsite must also include a prepared document that describes known and suspected properties likely to be exhibited and notification of potential hazards. The institution may be required to create a Safety Data Sheet (SDS) for the material.

-

Nanomaterial Disposal

- All waste should be kept in hazardous waste containers and labeled for pickup from EHS within 90 days of waste generation.

- All equipment that contacts nanomaterials during work processes should be disposed of as hazardous waste.

- Waste should never be poured down the drain or placed in trash bins.

- Visit the EHS Safety Portal to request hazardous waste pickup.

-

Emergency Procedures

- In the event of a spill, safety always comes first.

- Alert and clear everyone in the immediate area where the spill occurred.

- Always wear appropriate PPE when cleaning up a spill.

- If you are unable to contain the spill yourself, call Tyler McCord for assistance.

- If you are able to clean up the spill yourself, you may visit the EHS Safety Portal to request hazardous waste pickup for the cleanup materials.

- For liquid suspension spills, absorb using appropriate sorbents.

- For dry spills, clean with a HEPA vacuum or moist sorbent pads, or wet the material with an appropriate solvent and wipe with a dry cloth. Only use HEPA-rated vacuums; using non-HEPA vacuums can release nanomaterials directly into the surrounding atmosphere. HEPA vacuuming is not recommended for reactive materials, as they may react with other materials collected in the vacuum, or with components of the vacuum itself.

- Collect the residue, place in a container, and contact EHS for disposal at 517-355-0153.

-

Training

- All individuals handling nanomaterials should receive the following training, and training should be documented (topics covered, date, employee names and signatures).

- Chemical Hygiene, Laboratory Safety, and Hazardous Waste Initial training.

- Laboratory-specific training for work with nanomaterials must include information on the relatively greater hazards of working with nanomaterials, and on the uncertainty of health effects.

-

Control Banding Strategy

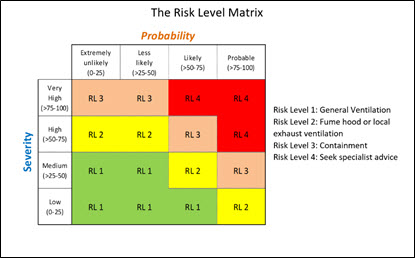

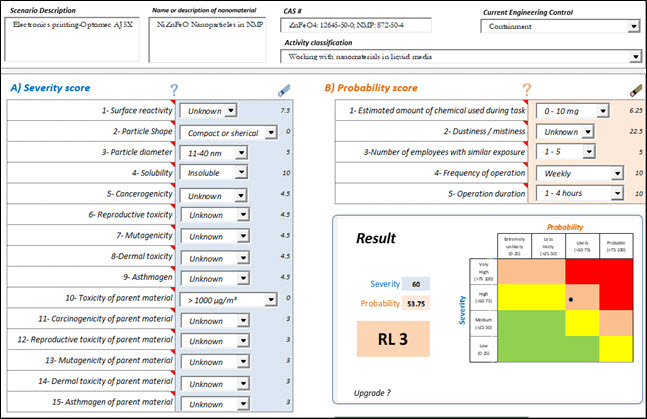

Because there are no established exposure limits for nanomaterials, EHS uses a Control Banding strategy to determine the level of containment appropriate for a work process involving nanomaterials. Control Banding is a qualitative exposure assessment strategy employed by industrial hygienists when working with chemicals that do not have quantitative exposure limits (e.g. 5 parts per million). The Control Banding tool used by MSU EHS, CB Nanotool, aggregates information about the nanomaterial and work process to assign Severity and Probability scores. The Severity and Probability scores are plotted on the Risk Level Matrix, which contains four Risk Levels with associated control measures. An example CB Nanotool assessment for a 3D printed electronics task using a nanoparticle-containing ink is found below.

The CB Nanotool only evaluates inhalation exposure. EHS may prescribe additional controls due to other nanomaterial properties such as dermal toxicity, explosivity, and reactivity. Hazards from other chemicals used in the nanomaterial work process may also change control prescriptions.

Resources

- CB Nanotool

- World Health Organization Guidelines on Protecting Workers from Potential Risks of Manufactured Nanomaterials(PDF)

- CDC National Institute for Occupational Safety and Health (NIOSH) Nanotechnology

- NIOSH General Safe Practices for Working with Engineered Nanomaterials in Research Laboratories(PDF)

- OSHA Fact Sheet: Working Safety with Nanomaterials(PDF)